How Surface Protection Film Can Save Your Surfaces from Damage During Renovations

- mavtinstith7

- Aug 23, 2024

- 4 min read

In today's fast-paced world, preserving the pristine condition of your surfaces is more challenging than ever. Whether you're a manufacturer, construction professional, interior designer, or a DIY enthusiast, maintaining the longevity and aesthetics of your surfaces is crucial. That's where surface protection film comes into play. This innovative solution not only shields your surfaces from damage but also enhances their appearance, making it a must-have for anyone looking to maximize efficiency and save money.

Understanding Surface Protection Film

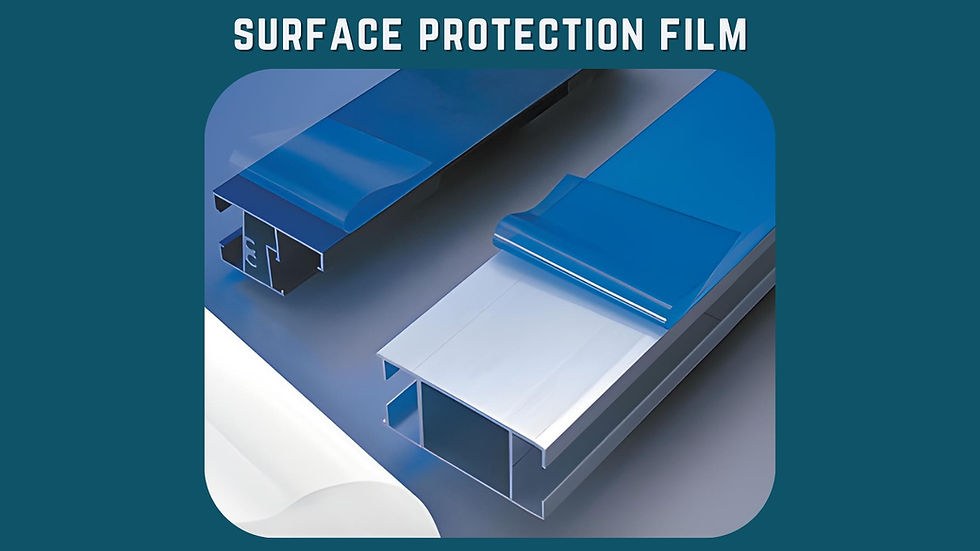

What is Surface Protection Film?

Surface protection film is a highly specialized type of plastic sheeting designed to shield surfaces from scratches, scuffs, dust, dirt, UV rays, and more. It's commonly used on furniture, walls, floors, and appliances to preserve their natural beauty and extend their lifespan. This film acts as a barrier, absorbing wear and tear while keeping the underlying surface in pristine condition.

Why is it Used?

The primary purpose of surface protection film is to safeguard surfaces from various forms of damage. Everyday activities can inadvertently cause scrapes, scratches, or scuffs, and even seemingly harmless dust and dirt can degrade the quality of your surfaces over time. Additionally, UV rays can cause discoloration and fading. Surface protection film provides an invisible armor against these damaging agents, ensuring that your surfaces remain in top-notch condition.

Common Materials Used

Surface protection films are made from various materials, each with its own set of characteristics:

Polyethylene (PE): Known for its flexibility and durability, PE is a popular choice for surface protection films.

Polyvinyl Chloride (PVC): PVC offers excellent resistance to chemicals and is ideal for environments where spills are common.

Polypropylene (PP): PP films are known for their high tensile strength and resistance to abrasion.

Each material provides unique benefits, allowing you to choose the best option for your specific needs.

Types of Surface Protection Film

Adhesive Films

Adhesive films come in two main types:

Permanent Adhesive Films

Permanent adhesive films are designed to provide long-term protection. They are ideal for surfaces that require ongoing safeguarding, such as floors in high-traffic areas. The benefits of permanent adhesive films include:

Superior durability and resistance to wear

Long-lasting protection

Ideal for surfaces that need continuous protection

However, they can be challenging to remove and may leave residue behind.

Removable Adhesive Films

Removable adhesive films offer temporary protection and are perfect for short-term projects, such as construction or renovation. Their advantages include:

Easy application and removal

No residue left behind

Suitable for projects with a defined end date

While they are less durable than permanent films, their ease of use makes them a popular choice for temporary applications.

Non-Adhesive Films

Non-adhesive films do not have a sticky backing and are held in place by static or friction. These films are ideal for surfaces that need protection without the risk of adhesive residue. Suitable applications include:

Protecting glass surfaces during transportation

Covering carpets and floors during painting projects

Shielding furniture during moves

Non-adhesive films are easy to apply and remove, making them a versatile solution for various scenarios.

Customizable Films

For those with specific requirements, customizable films offer tailored solutions. Options for customization include:

Thickness: Choose the ideal thickness based on the level of protection needed.

Size: Order films in custom sizes to fit your surfaces perfectly.

Color: Select from a range of colors to match your aesthetic preferences.

Customizable films allow you to get the exact protection you need, ensuring optimal performance and satisfaction.

Key Benefits of Surface Protection Film

Scratch and Abrasion Protection

One of the primary benefits of surface protection film is its ability to prevent scratches and abrasions. Whether it's a high-traffic floor, a delicate piece of furniture, or an appliance, the film acts as a barrier against physical damage. This protection is especially crucial in environments where surfaces are constantly exposed to wear and tear.

Dust and Debris Protection

Surface protection films play a vital role in keeping surfaces clean and free from contaminants. By preventing dust and dirt from settling directly on the material, the film makes it easier to maintain a clean environment. This feature is particularly beneficial in construction sites, manufacturing facilities, and other settings where cleanliness is essential.

Chemical Resistance

In environments where spills and exposure to corrosive substances are common, surface protection films provide an extra layer of defense. These films are resistant to a wide range of chemicals, ensuring that spills can be cleaned up quickly without causing damage to the underlying surface.

Cost-Effectiveness

Compared to other protective methods, surface protection film offers a cost-effective solution. The initial investment in high-quality film is relatively low, and the long-term savings from reduced repair and replacement costs make it a smart choice for businesses and individuals alike.

Long-Term Savings and Value

By extending the lifespan of your surfaces, surface protection film provides significant long-term savings. The reduced need for repairs and replacements translates to lower maintenance costs and higher overall value, making it an excellent investment for any commercial space.

Applications of Surface Protection Film

Construction and Renovation

In construction and renovation projects, surface protection film is indispensable for protecting floors, walls, and fixtures. It prevents damage from tools, materials, and foot traffic, ensuring that the finished project looks flawless.

Manufacturing

During production and assembly, surface protection film safeguards components from scratches, dust, and debris. This protection is vital for maintaining the quality and integrity of the final product.

Automotive Industry

The automotive industry uses surface protection film to protect vehicle parts and surfaces from damage during manufacturing and transportation. This film ensures that cars arrive at dealerships in pristine condition, ready for sale.

Electronics and Appliances

Sensitive components and surfaces in electronics and appliances require extra care. Surface protection film provides the necessary protection during manufacturing, assembly, and shipping, preventing damage and ensuring optimal performance.

Furniture and Retail

In the furniture and retail sectors, surface protection film prevents damage during shipping and handling. This protection is crucial for maintaining the appearance and value of products, ensuring customer satisfaction.

Comentarios